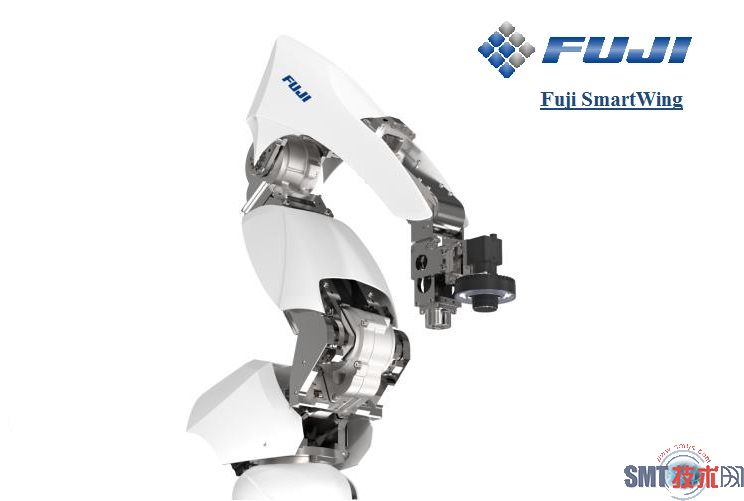

富士机械研制小型5轴多关节机械臂 Fuji SmartWing

为了应对在SMT后道工序中存在多种繁琐复杂的人工作业,富士机械研制小型5轴多关节机械臂SmartWing。SmartWing主要有小型化、免示教、高精度、前端带相机这4个特点。该机械臂的活动半径为710mm,前端臂体的宽度仅为65mm,与其它同类产品相比体型缩小了30~40%。SmartWing可多台密集配置使用,启动时不需要示教过程,简化用户的设置环境,一个生产程序可对应多条生产线。SmartWing在多关节机械臂的领域内首先达到±0.3mm的作业精度。(重复精度为±0.05mm)。SmartWing凭借高精度动作以及臂体前端安装的相机可以识别、补正作业对象以及基准点等的位置,能够相对于识别对象高精度执行作业。SmartWing是迄今为止操作方法最简单、任何人都能掌握的多关节机械臂。在FUJI智能工厂的整体构想中担当十分重要角色,它会为生产现场带来质的改变。

To meet wide range of manual work in different processes after the SMT, SmartWing, a compact five-axis multi-joint robot, has been developed. SmartWing has four main features: compact size, no on-machine teaching necessity, high accuracy, and a recognition camera equipped at the tip of the arm as standard. While the robot can extend to 710 mm around itself, the narrow design of the arm makes the robot very slim with its tip section being 65 mm. This means that the robot is slimmer by 30 to 40% compared with equivalent products from other manufactures. This slim arm allows multiple robots to be placed close together, reduce time and cost for automation. SmartWing will contribute greatly to automation in processes after the SMT process. these will make a difference at production sites with our concept of Fuji Smart Factory.